Boost Operational Efficiency with Turnkey

Boost Operational Efficiency with Turnkey Solutions and Advanced Machinery At Brinda Pharma Technologies Private Limited, we understand the critical need

Introducing our Static Pass Box – the ideal solution for controlled access and contamination prevention. Our Static Pass Box offers seamless material transfer while adhering to the highest cleanliness standards. With advanced features and robust construction, it ensures a hygienic environment for critical operations. Equipped with an interlocking mechanism and HEPA filters, our Pass Box prevents cross-contamination and delivers superior air purification. Safety features like door open alarms and a reliable fire suppression system provide added protection. Discover the efficiency and reliability of our customizable Static Pass Box for your specific industry needs.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room air showers for various applications in the following areas:

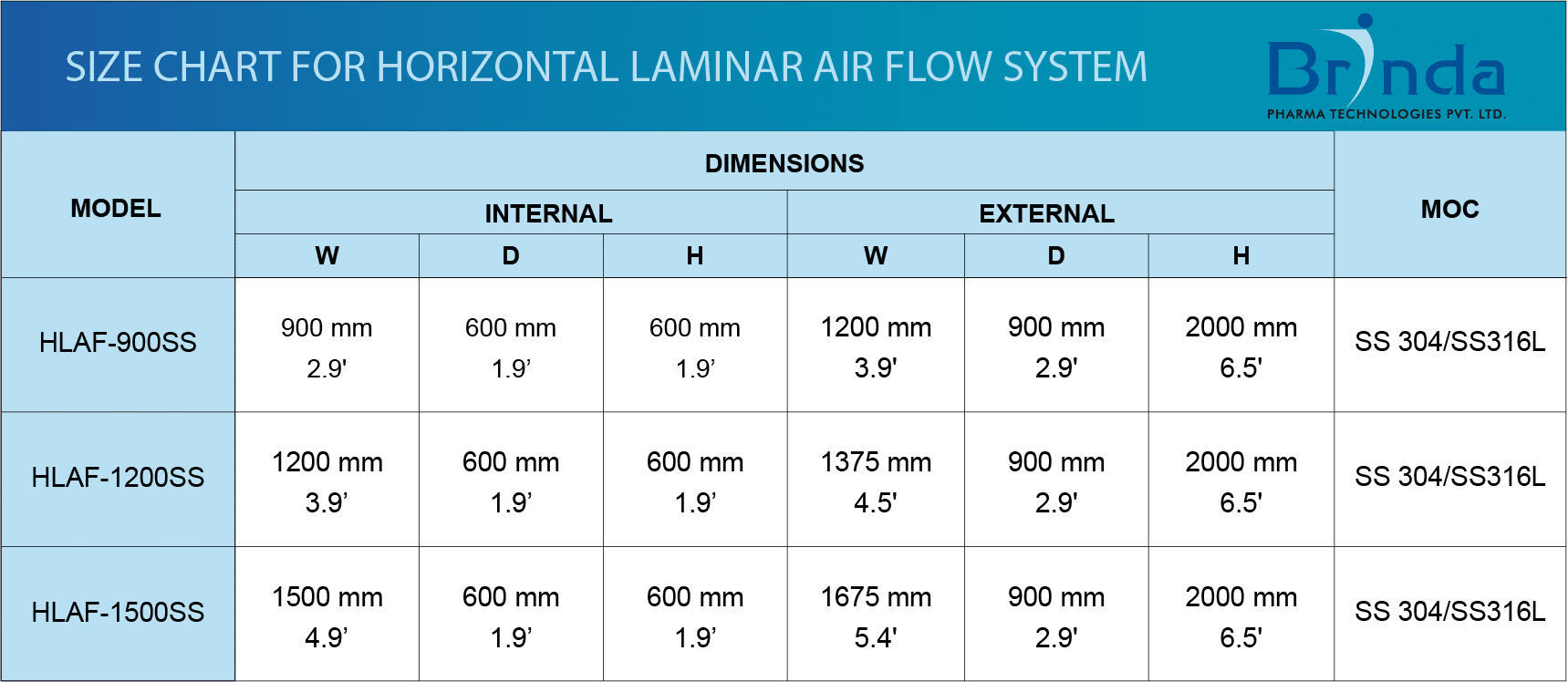

The Horizontal Laminar Air Flow – HLAF system is an advanced air filtration solution designed to emit clean air Horizontally inside its working chamber to create a controlled and sterile environment by limiting the contamination. With its advanced technology, the system ensures a continuous flow of clean air and effectively minimizing the risk of contamination.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality Horizontal Laminar Air Flow systems for various applications in the following areas:

The Horizontal Laminar Air Flow (HLAF) system works on basic principle of Air filtration. It sucks the ambient room air. This air goes through the filters called high-efficiency particulate air (HEPA) filters. HEPA filters removes the contaminants particles—up to 99.999% down to 0.3 microns.

After the air gets filtered, it flows out in one direction, horizontally, parallel to the workspace.

It is a standalone system and does not relies on any external factors other than power supply.

| Accessory | Description |

|---|---|

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| UV Light | UV light for sterilization and improved contamination control |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

Can a Horizontal Laminar Air Flow System be customized?

Yes, Horizontal Laminar Air Flow systems can be customized based on specific requirements, including size and various available sash options. There are many possible customizations and configuration to discuss in more details; you can connect with our Sales Team.

How are horizontal laminar airflow systems different from vertical laminar airflow systems?

The main difference between horizontal and vertical laminar airflow systems lies in the direction of the air flow. In a horizontal laminar airflow system, the filtered air moves in a horizontal direction across the work surface. In contrast, a vertical laminar airflow system directs the filtered air vertically from the top towards the workspace.

Does Brinda Pharma Technologies provide delivery & installation to my destination?

As a leading manufacturer and exporter we provide delivery orders across the world. We also provide products with installation & validation, as well as an annual maintenance contract to ease your operation. Reach out to our Sales Team to discuss any questions related to Delivery & Installation.

Boost Operational Efficiency with Turnkey Solutions and Advanced Machinery At Brinda Pharma Technologies Private Limited, we understand the critical need

What is Lab Furniture? Lab furniture refers to specially designed fixtures and equipment used in laboratories to support scientific research,

Smart Cleanroom Tips to Enhance Lab Safety and Productivity Maintaining a cleanroom environment in pharmaceutical labs is not just about

Reduce Downtime & Improve Efficiency with Our Lab Furniture Systems In the pharmaceutical industry, compliance is non-negotiable. That’s why at

Cleanroom Rules Leave personal items outside the controlled environment If items such as keys, wallets, phones, etc. must be brought into

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

| Accessory | Description |

|---|---|

| Pressure Gauge | Accurate pressure gauge for monitoring and maintaining optimal airflow and pressure levels. |

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| UV Light | UV light for sterilization and improved contamination control |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

| Flame Proof System (FLP) | A Complete or partial Flame Proof System along with FLP Lights to accommodate safe working environment and prevent fire hazards. |

Error: Contact form not found.

Error: Contact form not found.