7 Essential Tips for Clean

Smart Cleanroom Tips to Enhance Lab Safety and Productivity Maintaining a cleanroom environment in pharmaceutical labs is not just about

Introducing our Static Pass Box – the ideal solution for controlled access and contamination prevention. Our Static Pass Box offers seamless material transfer while adhering to the highest cleanliness standards. With advanced features and robust construction, it ensures a hygienic environment for critical operations. Equipped with an interlocking mechanism and HEPA filters, our Pass Box prevents cross-contamination and delivers superior air purification. Safety features like door open alarms and a reliable fire suppression system provide added protection. Discover the efficiency and reliability of our customizable Static Pass Box for your specific industry needs.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room air showers for various applications in the following areas:

Experience High standard safety and protection in your laboratory with our Bio Safety Cabinet (BSC). It is also known a Biological Cabinet. Designed & manufactured to protect product, personnel and the environment from biohazardous materials, It offers advanced features and superior performance. Whether you’re in research, healthcare, or pharmaceuticals, our Bio Safety Cabinet ensures the highest level of containment, safety.

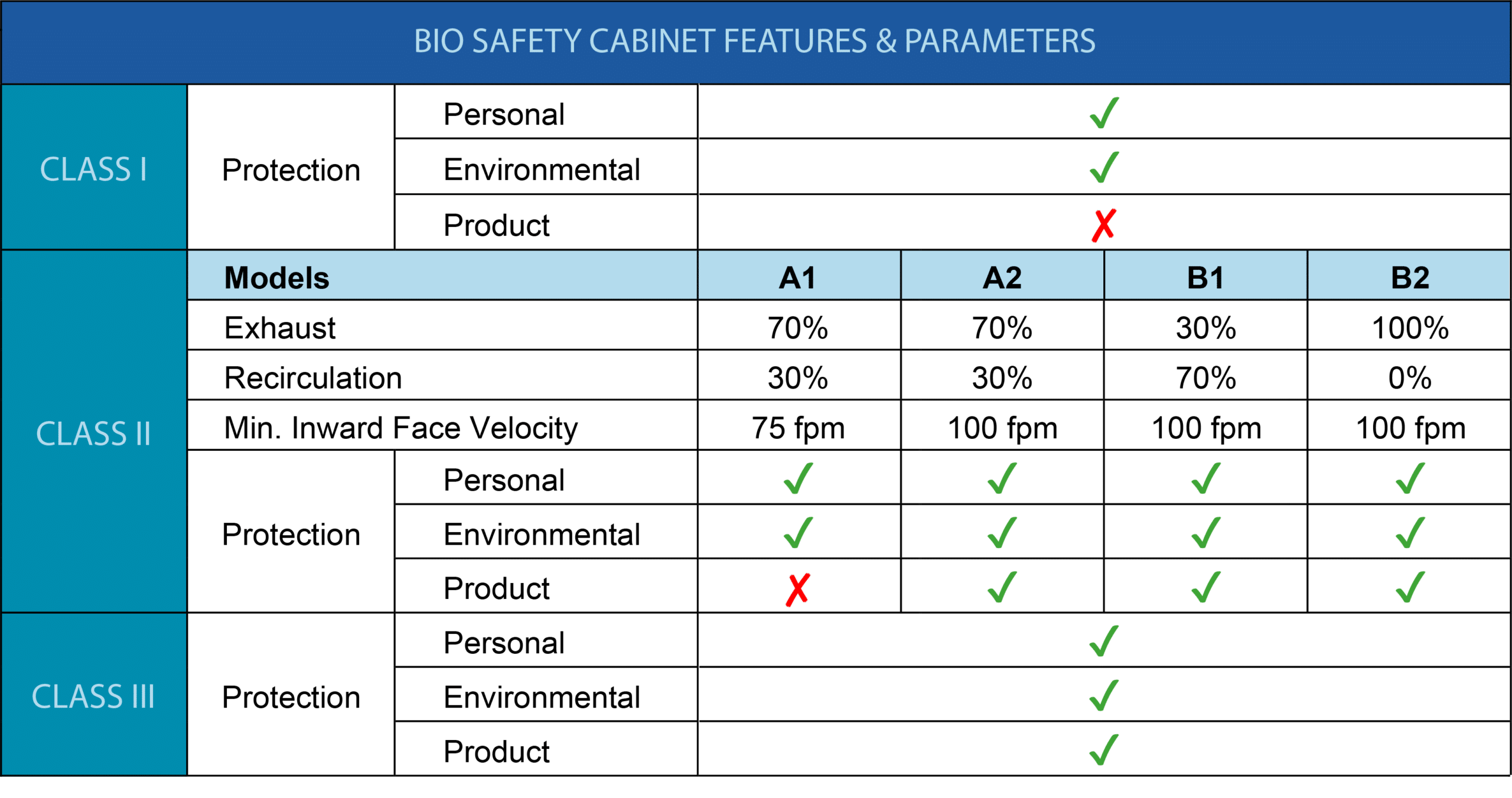

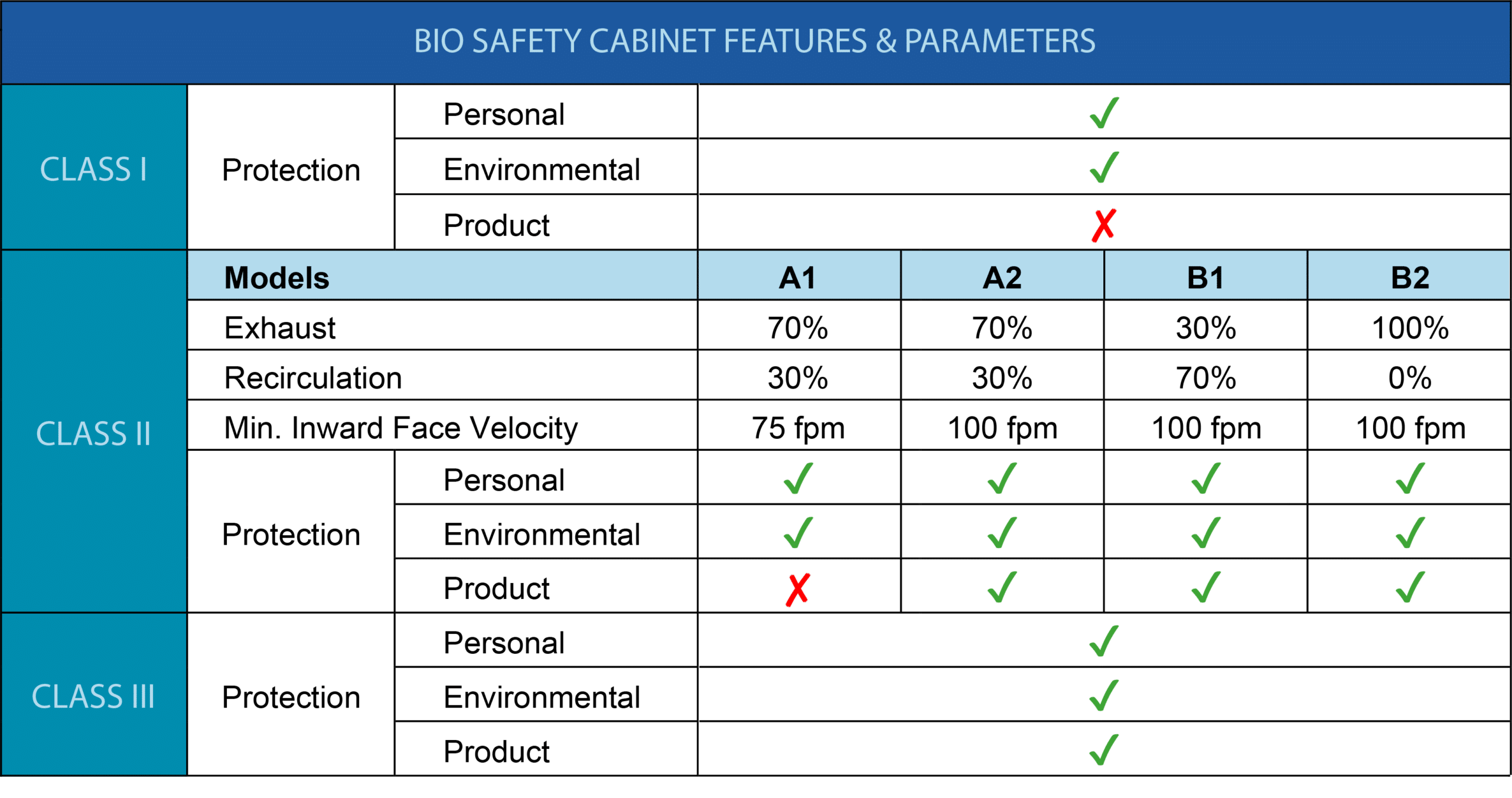

We manufacture standard models of Bio Safety Cabinet in Class I, Class II, Class III where Class II, Class III models are highly used in the industry. We do also customize the Bio Safety Cabinets as per your unique process requirement.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality Bio safety cabinets for various applications in the following areas:

Experience High standard safety and protection in your laboratory with our Bio Safety Cabinet (BSC). It is also known a Biological Cabinet. Designed to protect product, personnel and the environment from bio hazardous materials, It offers advanced features and superior performance. Whether you’re in research, healthcare, or pharmaceuticals, our Bio Safety Cabinet ensures the highest level of containment, safety.

We manufacture standard models of Bio Safety Cabinet in Class I, Class II, Class III where Class II, Class III models are highly used in the industry. We do also customize the Bio Safety Cabinets as per your unique process requirement.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality Bio safety cabinets for various applications in the following areas:

The working principle of Bio Safety Cabinet is very unique and complicated as the different Class & Models have different working principle. There are three Class of Bio Safety Cabinets Class I, Class II & Class III. There are also different models under the different Class according to its capability to offer protection as well as size, material and specification of Bio Safety Cabinet

To simplify everything we have created a brief overview of different Class & Models of Bio Safety Cabinet.

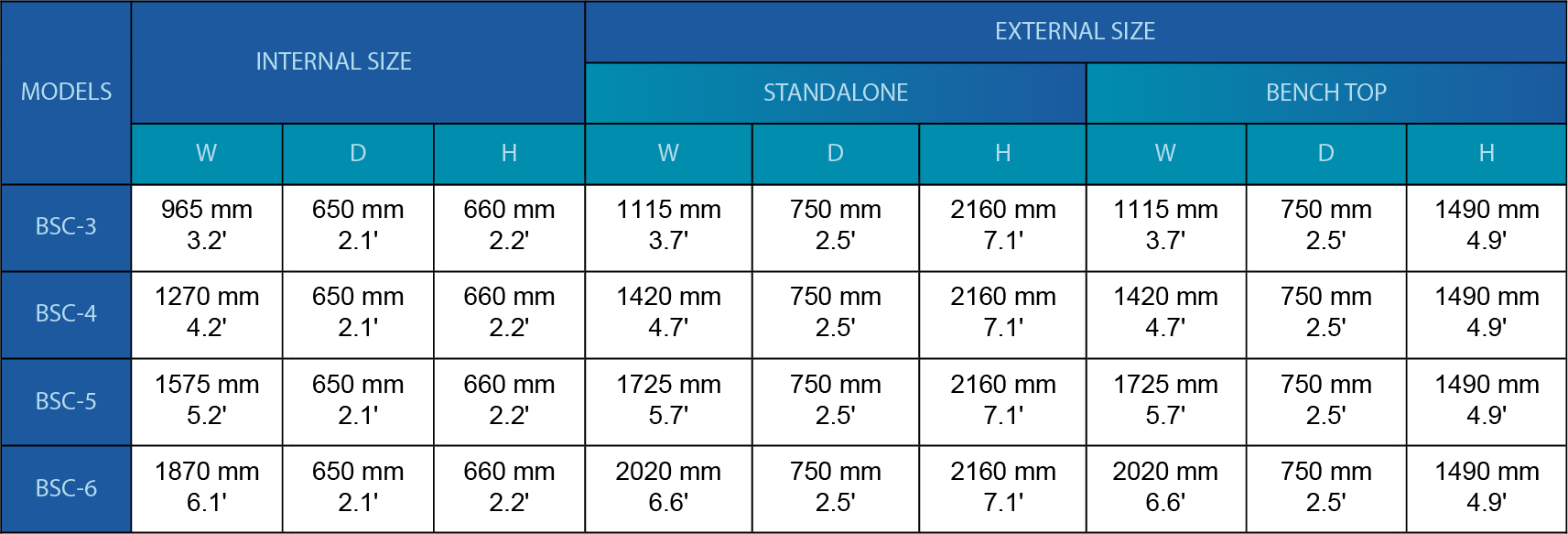

Brinda Pharma Technoliges manufactures all Bio Safety Cabinets in standalone and bench top variation. Where standalone model is mounted on a castor wheel structure for easy mobility and bench top model can be placed on any existing working platform. We have four option in width of bio safety cabinet which comes in 3, 4, 5 and 6 feet models. All models comes with wrist rest for easy operation.

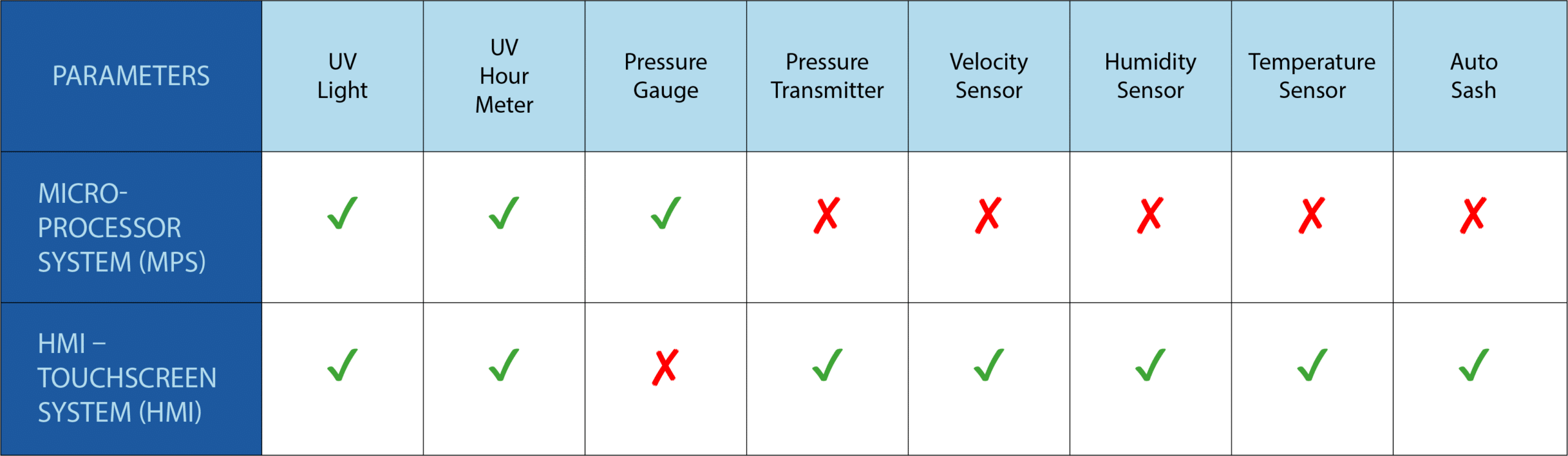

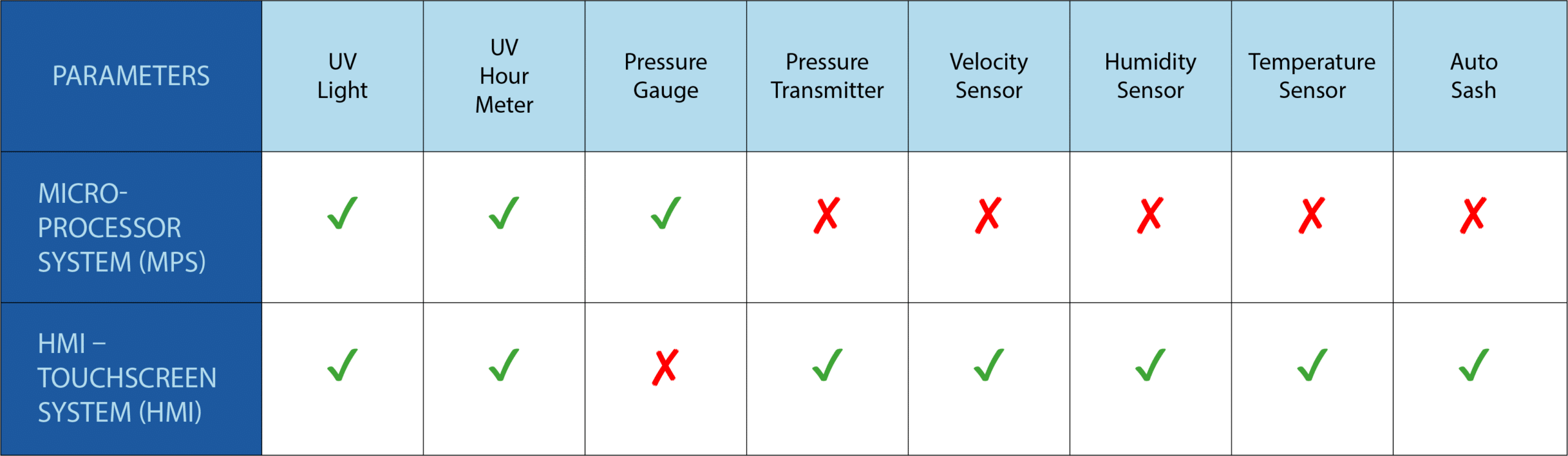

Brinda Pharma Technoliges manufactures all Bio Safety Cabinet models in two control configuration. One is normal microprocessor based control system which is minimal and cost effective. Another one is advance HMI based Touch Screen System where user can monitor and operate the Bio Safety Cabinet from the Touch Screen interface which makes it easier to use.

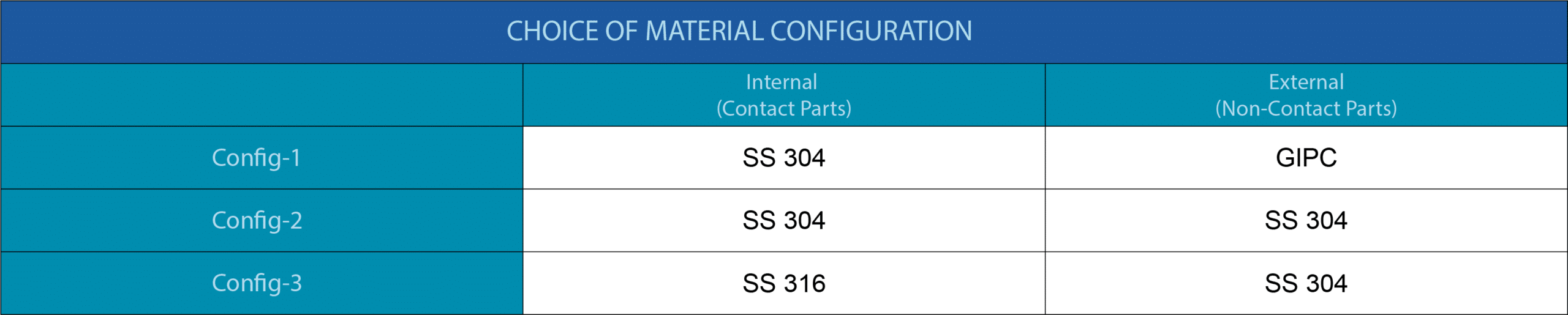

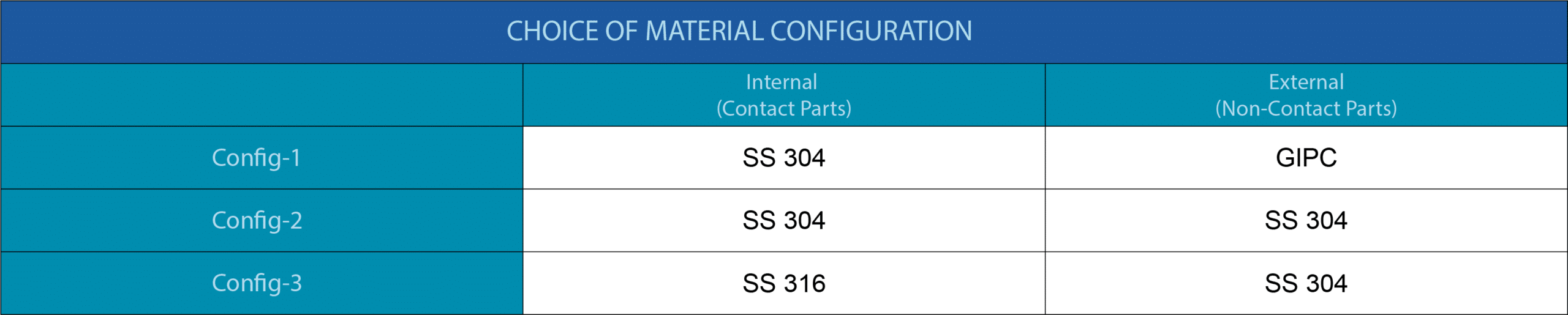

Brinda Pharma Technologies manufactures all Bio Safety Cabinet in various combination of materials like Galvanized Iron powder coated, Stainless Steel 304 as well as Stainless Steel 316. The most common model that we sell is Config-1, Where the Internal Contact Parts of the cabinet is made in S.S. 304 and the External Non-Contact Parts is made in Powder Coated Galvanized Iron.

| Accessory | Description |

|---|---|

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

How should I use a bio safety cabinet?

Before Using the Bio Safety cabinet it’s necessary to wear the appropriate personal protective (PPE), including gloves, lab coats, and eye protection. Then disinfect the work surface before and after each use. Keep the Sash of the BSC closed as much as possible during the operation to maintain the airflow.

How often should bio safety cabinets be serviced and certified?

Bio safety cabinets should be serviced and certified at least annually to ensure they are operating properly and providing the necessary containment. However, specific requirements may vary depending on local regulations and institutional policies. Regular maintenance and certification are essential for the safety of personnel and the integrity of the work being performed. Also the cleaning of internal chamber of Bio Safety cabinet is required before & after each operational cycle with proper cleaning agents.

Are bio safety cabinets suitable for all types of biological materials?

Bio safety cabinets are suitable for a wide range of biological materials, including microorganisms, cell cultures, and tissues. However, the appropriate class of biosafety cabinet should be selected based on the specific hazards associated with the materials being handled. Highly infectious or hazardous agents may require a higher level of containment than lower-risk materials.

Can bio safety cabinets be used for chemical fume containment?

While bio safety cabinets provide a degree of chemical fume containment, they are primarily designed for biological hazards. For chemical fume containment, Fume Hoods are recommended, as they are specifically engineered to handle and contain chemical substances.

What precautions should be taken when working with a bio safety cabinet?

When working with a bio safety cabinet, it is important to follow proper aseptic techniques and good laboratory practices. Minimize movement and disruptions inside and outside the cabinet to maintain airflow patterns. Avoid overloading the cabinet with equipment or materials, which can impede airflow. Regularly clean and decontaminate the cabinet, including the work surface and interior components. Familiarize yourself with the specific operating procedures and guidelines provided by the manufacturer and your institution.

Can a bio safety cabinet be customized to meet specific laboratory or facility requirements?

Yes, we do manufacture bio safety cabinets as per complex and unique user requirements. Kindly connect with our Sales Team to discuss the same.

Does Brinda Pharma Technologies provide delivery & installation to my destination?

As a leading manufacturer and exporter we provide delivery across the world. We also provide products with installation & validation, as well as an annual maintenance contract to ease your operation. Reach out to our Sales Team to discuss any questions related to Delivery & Installation.

Smart Cleanroom Tips to Enhance Lab Safety and Productivity Maintaining a cleanroom environment in pharmaceutical labs is not just about

Reduce Downtime & Improve Efficiency with Our Lab Furniture Systems In the pharmaceutical industry, compliance is non-negotiable. That’s why at

Cleanroom Rules Leave personal items outside the controlled environment If items such as keys, wallets, phones, etc. must be brought into

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

| Accessory | Description |

|---|---|

| Pressure Gauge | Accurate pressure gauge for monitoring and maintaining optimal airflow and pressure levels. |

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| UV Light | UV light for sterilization and improved contamination control |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

| Flame Proof System (FLP) | A Complete or partial Flame Proof System along with FLP Lights to accommodate safe working environment and prevent fire hazards. |

© Copyright Brinda Pharma Technologies 2024. All Rights Reserved

Error: Contact form not found.

Error: Contact form not found.