What is Laminar Air Flow

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

Air Shower is a equipment which helps eliminate contamination through optimizing the people’s movement inside the facility/area. It uses high velocity filtered air to remove dirt and germs from people’s clothes and bodies before they enter the facility. It acts as a barrier to keep the contamination out of the area. This ensures that the area remains extremely clean and safe for particular process and helps improve the quality of products.

The special features of air showers include their effective filtration system, fast airflow, and safety mechanisms like interlocking doors and programmable controls.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room Air Shower systems for various applications in the following areas:

| Accessory | Description |

|---|---|

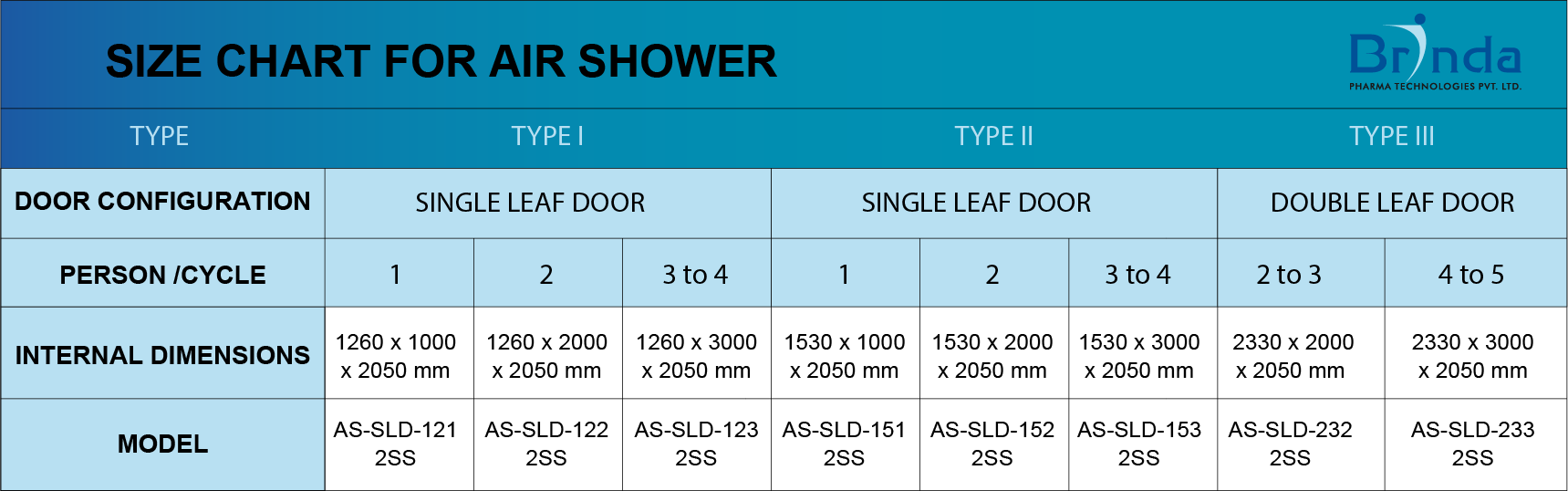

| Vertical/Horizontal Door Openiong | Various types of door configuration to optimize and integrate the Air Shower |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

Why air shower is essential for the clean room facility?

Air showers are essential for Clean room facilities as they contribute to contamination control, Quality and regulatory compliance. By effectively removing contaminants from individual before they enter controlled environments, air showers play a vital role in maintaining the integrity and cleanliness of facilities across various industries.

Does an Air Shower increase the product quality and integrity in clean room facility?

Yes..!! In industries such as pharmaceuticals, biotechnology, and microelectronics, the presence of contaminants can have greater consequences on product quality and integrity. Even small particles or microorganisms can impact the performance, reliability, and functionality of sensitive products and processes. Air showers help ensure that personnel entering the facility are free from contaminants, protecting the quality and integrity of the products being manufactured or developed.

Is there any advantage in regulatory compliance by having an Air Shower?

Many industries, such as Pharmaceuticals and Healthcare, are subject to strict regulatory guidelines and contamination control. Air Showers are often a requirement to meet these regulatory requirements. By implementing Air Shower systems, facilities demonstrate their commitment to maintaining a controlled and clean environment, ensuring compliance with industry regulations and standards.

Does Brinda Pharma Technologies provide delivery & installation to my destination

As a leading manufacturer and exporter we provide delivery orders across the world. We also provide products with installation & validation, as well as an annual maintenance contract to ease your operation. Reach out to our Sales Team to discuss any questions related to Delivery & Installation.

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

Explore innovative cleanroom and laboratory solutions for modern pharmaceutical facilities The pharmaceutical industry is evolving rapidly, driven by stricter regulations,

Transforming Hospital Care with Cutting-Edge Lab & Cleanroom Solutions In modern healthcare, hospitals are no longer defined only by skilled

What is Process Equipment? Process equipment refers to a broad range of machinery, tools, systems, and components specifically designed to

Boosting Safety & Compliance in Chemical Plants and API Manufacturing with the Right Infrastructure In today’s chemical and API manufacturing

Reduce Waste & Improve Safety Through Better Airflow & Material Transfer Systems In the chemical industry, maintaining safety and preventing

Step-by-Step Installation Guide for Static Pass Box, Dynamic Pass Box & Hatch Pass Trough Maintaining contamination-free material transfer is essential

Transforming Biotechnology Labs with Smart Furniture Solutions In biotechnology laboratories, every second counts precision, safety, and efficiency are critical to

Upgrade Your Pharma Lab with Advanced Cleanroom Solutions In the pharmaceutical industry, every step matters from early-stage research and drug

Ensure Precision with Brinda Pharma’s Visual Inspection Booth (cGMP Model) In the pharmaceutical and biotechnology industries, product quality and patient

| Accessory | Description |

|---|---|

| Pressure Gauge | Accurate pressure gauge for monitoring and maintaining optimal airflow and pressure levels. |

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| UV Light | UV light for sterilization and improved contamination control |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

| Flame Proof System (FLP) | A Complete or partial Flame Proof System along with FLP Lights to accommodate safe working environment and prevent fire hazards. |

Error: Contact form not found.

Error: Contact form not found.