Process Equipment and Sterile Mixing

What is Process Equipment? Process equipment refers to a broad range of machinery, tools, systems, and components specifically designed to

Introducing our Static Pass Box – the ideal solution for controlled access and contamination prevention. Our Static Pass Box offers seamless material transfer while adhering to the highest cleanliness standards. With advanced features and robust construction, it ensures a hygienic environment for critical operations. Equipped with an interlocking mechanism and HEPA filters, our Pass Box prevents cross-contamination and delivers superior air purification. Safety features like door open alarms and a reliable fire suppression system provide added protection. Discover the efficiency and reliability of our customizable Static Pass Box for your specific industry needs.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room air showers for various applications in the following areas:

The Reverse Laminar Air Flow System (RLAF) also known as Sampling Booth as well as Dispensing Booth. It represents the pinnacle of contamination control technology. Tailored to meet the rigorous standards of cleanliness required in sensitive operational settings, this system employs sophisticated mechanisms to capture and eliminate airborne contaminants while performing Sampling & Dispensing Activity for any powder, liquid form material. It establishes a barrier against the spread of particles which results in a clean environment & increased safety for the operator.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality Reverse Laminar Air Flow System for various applications in the following areas:

Our Reverse Laminar Air Flow system (RLAF) relies on an innovative principle to combat contamination effectively. The system generates a reverse airflow pattern, that is one the reason that this product is named after it. Capturing and Containing contaminants within a designated area is a easy job with RLAF. The contaminated air is suctioned through the working chamber using stage 1 filtration, later air passes through the stage 2 filtration and finally Clean Air is again flushed into the working chamber at high velocity through Stage 3 fitration which is a HEPA Filter. This air flow pattern ensures that the working chamber is always free from contaminants. The unique feature of the RLAF is that it is not dependent on any other external HAVC systems, It works with the power supply only. To Turn on the System, a keypad with various buttons is accomodated inside the chamber along with diffrential pressure gauges to monitor the diffrential pressure across the different filters. A Ligting system, Emergency Stop & optional clean down timer is also accomodated inside the chamber.

| Accessory | Description |

|---|---|

| Touch Screen Control Panel | User-friendly control panel for easy operation and adjustment of system settings. |

| Monochromatic Lighting | Energy-efficient LED lights or monochromatic lighting for enhanced visibility in the work area. |

| Pressure Gauge with Alarm | Accurate pressure gauge for monitoring and maintaining optimal airflow and pressure levels along with Customized alarm setting. |

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| Flame Proof System (FLP) | A Complete or partial Flame Proof System along with FLP Lights to accommodate safe working environment and prevent fire hazards. |

What are the applications of RLAF systems?

RLAF systems find applications in various industries, including pharmaceuticals, biotechnology, laboratories, cleanrooms, and manufacturing facilities. They are used to maintain sterile environments, prevent cross-contamination, and ensure product quality in critical operations.

What are the key features of RLAF systems?

Key features of RLAF systems include superior contamination control, high-efficiency filtration, customizable configurations, compliance with industry standards, and user-friendly operation. These systems are designed to provide exceptional performance and reliability for critical operations.

How do RLAF systems differ from traditional air filtration systems?

RLAF systems differ from traditional air filtration systems in their ability to create a reverse airflow pattern that prevents the escape of contaminants from the work area. Unlike traditional systems that rely on positive pressure, RLAF systems operate on negative pressure to contain contaminants effectively.

What maintenance is required for RLAF systems?

Regular maintenance is essential to ensure the efficiency and effectiveness of RLAF systems. This includes routine filter replacement, cleaning of the system components, and periodic inspections to identify any issues. Proper maintenance helps optimize air quality and prolong the lifespan of the system.

How can I choose the right RLAF system for my facility?

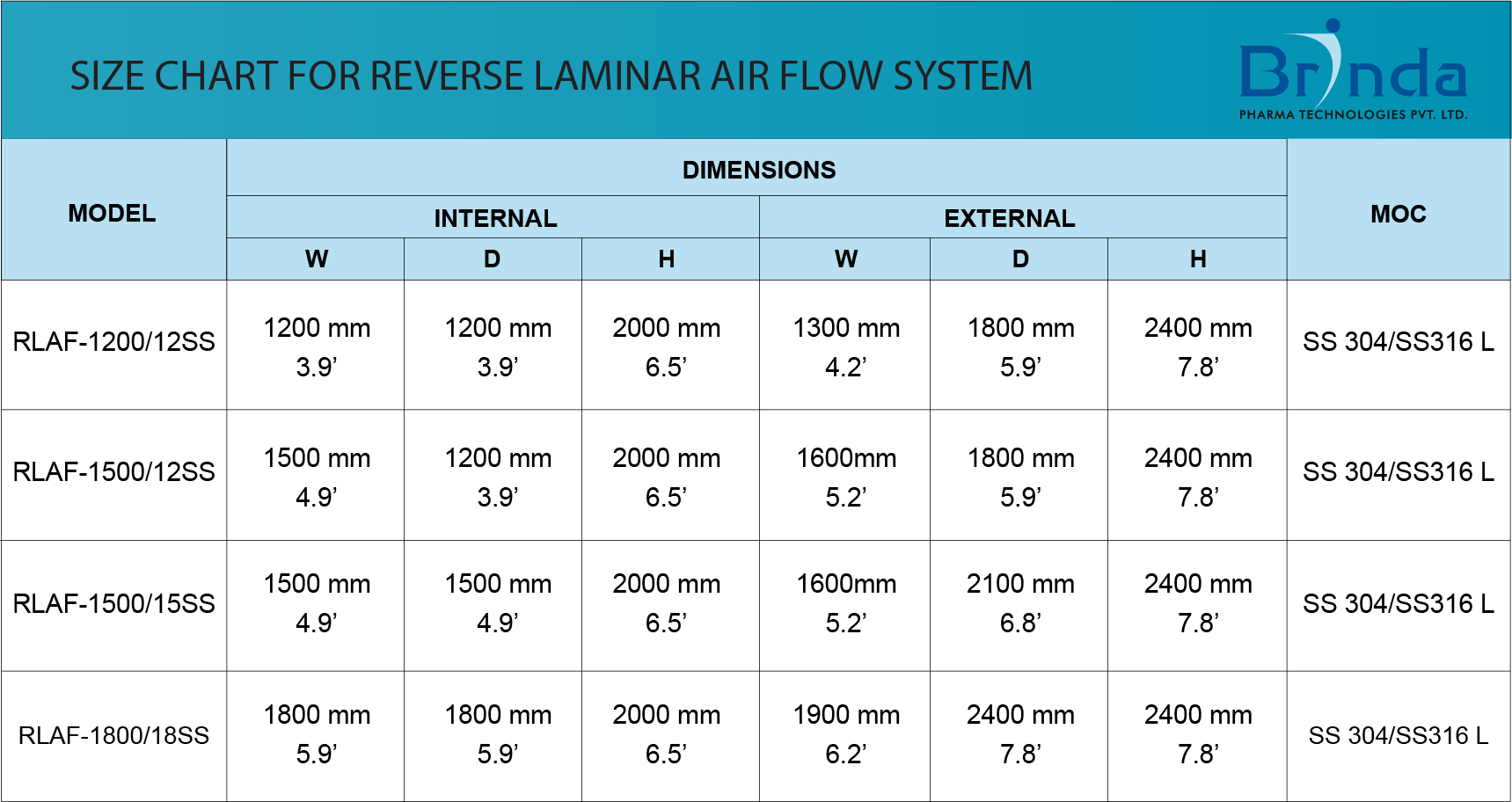

When choosing a RLAF system, consider factors such as the size of your area/room where the RLAF is required. One of the key things is to make sure that the internal chamber can easily accommodate your weighing scale, printer, container, drum, barrel and a operator for smooth operation. Our expert sales professionals can guide you to choose the right size and configurations for your application.

What are the safety considerations when using RLAF systems?

Safety considerations when using RLAF systems include proper installation by qualified professionals, regular maintenance to ensure optimal performance, adherence to cleanroom protocols, and training of personnel on system operation and safety procedures. For additional safety a complete flame proof system is also configured.

What is Flame Proof RLAF System and what is the use of it?

It is used when the operator is handling a sensitive product which can catch a fire. We do complete or partial Flame Proof System along with FLP Lights, control panel to accommodate safe working environment and prevent fire hazards.

Can RLAF systems be customized to meet specific requirements?

Yes, RLAF systems can be customized to meet the specific requirements of different industries and applications. This includes adjustable airflow settings, specialized filtration options, and integration with existing cleanroom infrastructure. . Our expert sales professionals can guide you to choose the right specifications and configurations for your application.

Does Brinda Pharma Technologies provide delivery & installation to my destination?

As a leading manufacturer and exporter we provide delivery orders across the world. We also provide products with installation & validation, as well as an annual maintenance contract to ease your operation. Reach out to our Sales Team to discuss any questions related to Delivery & Installation.

What is Process Equipment? Process equipment refers to a broad range of machinery, tools, systems, and components specifically designed to

Boosting Safety & Compliance in Chemical Plants and API Manufacturing with the Right Infrastructure In today’s chemical and API manufacturing

Reduce Waste & Improve Safety Through Better Airflow & Material Transfer Systems In the chemical industry, maintaining safety and preventing

Step-by-Step Installation Guide for Static Pass Box, Dynamic Pass Box & Hatch Pass Trough Maintaining contamination-free material transfer is essential

Transforming Biotechnology Labs with Smart Furniture Solutions In biotechnology laboratories, every second counts precision, safety, and efficiency are critical to

Upgrade Your Pharma Lab with Advanced Cleanroom Solutions In the pharmaceutical industry, every step matters from early-stage research and drug

Ensure Precision with Brinda Pharma’s Visual Inspection Booth (cGMP Model) In the pharmaceutical and biotechnology industries, product quality and patient

Choosing the Right Injectable Mixing Vessel for Sterile Manufacturing In the pharmaceutical and biotechnology industries, selecting the right Sterile Mixing

Ensuring Superior Cleanliness and Efficiency with Brinda Pharma’s Advanced De-Dusting Tunnel In the pharmaceutical, food, and chemical industries, even the

Reduce Contamination Risks with Brinda’s Air Shower Solutions In controlled environments like pharmaceutical cleanrooms, contamination is a constant threat to

| Accessory | Description |

|---|---|

| Pressure Gauge | Accurate pressure gauge for monitoring and maintaining optimal airflow and pressure levels. |

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| UV Light | UV light for sterilization and improved contamination control |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

| Flame Proof System (FLP) | A Complete or partial Flame Proof System along with FLP Lights to accommodate safe working environment and prevent fire hazards. |

Error: Contact form not found.

Error: Contact form not found.