What is Laminar Air Flow

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

Introducing our Static Pass Box – the ideal solution for controlled access and contamination prevention. Our Static Pass Box offers seamless material transfer while adhering to the highest cleanliness standards. With advanced features and robust construction, it ensures a hygienic environment for critical operations. Equipped with an interlocking mechanism and HEPA filters, our Pass Box prevents cross-contamination and delivers superior air purification. Safety features like door open alarms and a reliable fire suppression system provide added protection. Discover the efficiency and reliability of our customizable Static Pass Box for your specific industry needs.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room air showers for various applications in the following areas:

A Vertical Laminar Airflow Cabinet is a crucial equipment used in laboratories and cleanrooms to maintain a controlled environment for sensitive work. Its design facilitates downward airflow, keeping the workspace free of contaminants. Constructed with durable materials and advance filtration system which helps trapping particles as small as 0.3 microns. This setup ensures a sterile environment, crucial for tasks such as microbiological testing, pharmaceutical compounding, and electronics assembly. It helps safeguard both the materials being handled and the operators

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room Vertical Laminar Air Flow systems for various applications in the following areas:

| Accessory | Description |

|---|---|

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

Can a Vertical Laminar Air Flow Cabinet be customized?

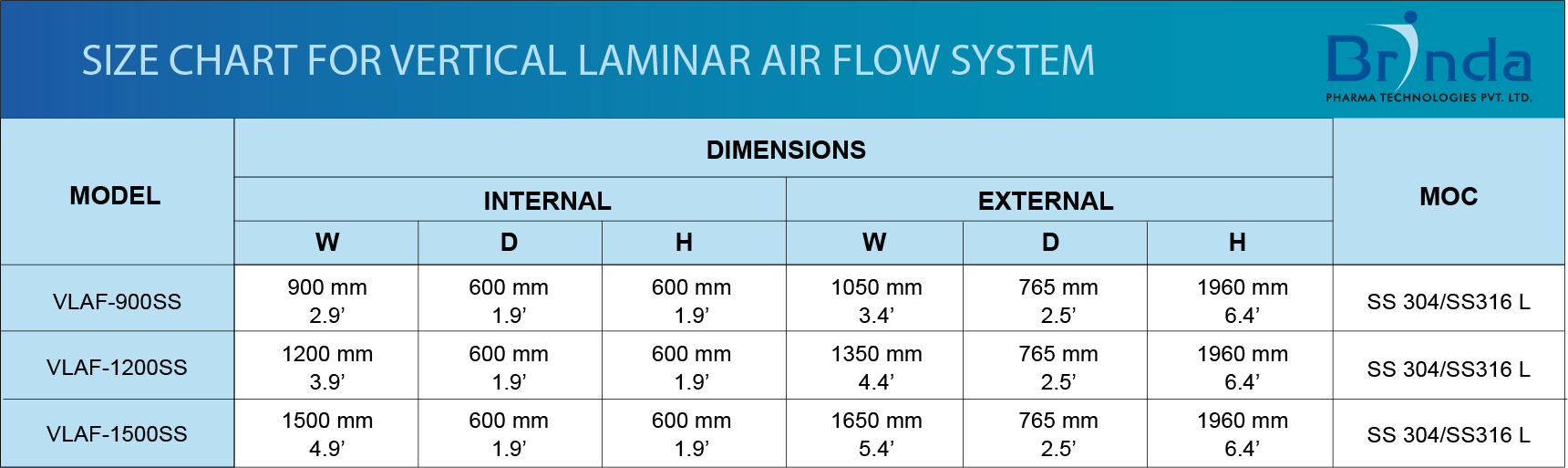

Yes, Vertical Laminar Air Flow systems can be customized based on specific requirements, including size. There are many possible customizations and configuration to discuss in more details; you can connect with our Sales Team.

How can I choose the right Vertical Laminar Air Flow Cabinet for my facility?

When choosing a system, consider factors such as the size of your area/room where it is required. One of the key things is to make sure that the internal chamber can easily accommodate your process. Our expert sales professionals can guide you to choose the right size and configurations for your application.

What maintenance is required for Vertical Laminar Air Flow Cabinet?

Regular maintenance is essential to keep the cabinet functioning optimally. Wipe down the interior and exterior surfaces of the cabinet using a mild disinfectant. Filter cleaning & replacement is also an important task to ensure the system’s effectiveness to eliminate contamination.

Does Brinda Pharma Technologies provide delivery & installation to my destination?

As a leading manufacturer and exporter we provide delivery orders across the world. We also provide products with installation & validation, as well as an annual maintenance contract to ease your operation. Reach out to our Sales Team to discuss any questions related to Delivery & Installation.

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

Explore innovative cleanroom and laboratory solutions for modern pharmaceutical facilities The pharmaceutical industry is evolving rapidly, driven by stricter regulations,

Transforming Hospital Care with Cutting-Edge Lab & Cleanroom Solutions In modern healthcare, hospitals are no longer defined only by skilled

What is Process Equipment? Process equipment refers to a broad range of machinery, tools, systems, and components specifically designed to

Boosting Safety & Compliance in Chemical Plants and API Manufacturing with the Right Infrastructure In today’s chemical and API manufacturing

Reduce Waste & Improve Safety Through Better Airflow & Material Transfer Systems In the chemical industry, maintaining safety and preventing

Step-by-Step Installation Guide for Static Pass Box, Dynamic Pass Box & Hatch Pass Trough Maintaining contamination-free material transfer is essential

Transforming Biotechnology Labs with Smart Furniture Solutions In biotechnology laboratories, every second counts precision, safety, and efficiency are critical to

Upgrade Your Pharma Lab with Advanced Cleanroom Solutions In the pharmaceutical industry, every step matters from early-stage research and drug

Ensure Precision with Brinda Pharma’s Visual Inspection Booth (cGMP Model) In the pharmaceutical and biotechnology industries, product quality and patient

| Accessory | Description |

|---|---|

| Pressure Gauge | Accurate pressure gauge for monitoring and maintaining optimal airflow and pressure levels. |

| Clean Down Timer | Timer feature for scheduling and automating the cleaning process, ensuring consistent cleanliness. |

| Pilot Light | Indicator light to signal the operational status of the system, providing visual feedback to users. |

| Buzzers | Audible alarms or buzzers to alert users of any anomalies or safety concerns, enhancing system safety. |

| UV Light | UV light for sterilization and improved contamination control |

| HMI+PLC Based Control System | To monitor and change various parameters from a single touchscreen interface which makes entire system easy to operate. |

| Flame Proof System (FLP) | A Complete or partial Flame Proof System along with FLP Lights to accommodate safe working environment and prevent fire hazards. |

Error: Contact form not found.

Error: Contact form not found.