7 Essential Tips for Clean

Smart Cleanroom Tips to Enhance Lab Safety and Productivity Maintaining a cleanroom environment in pharmaceutical labs is not just about

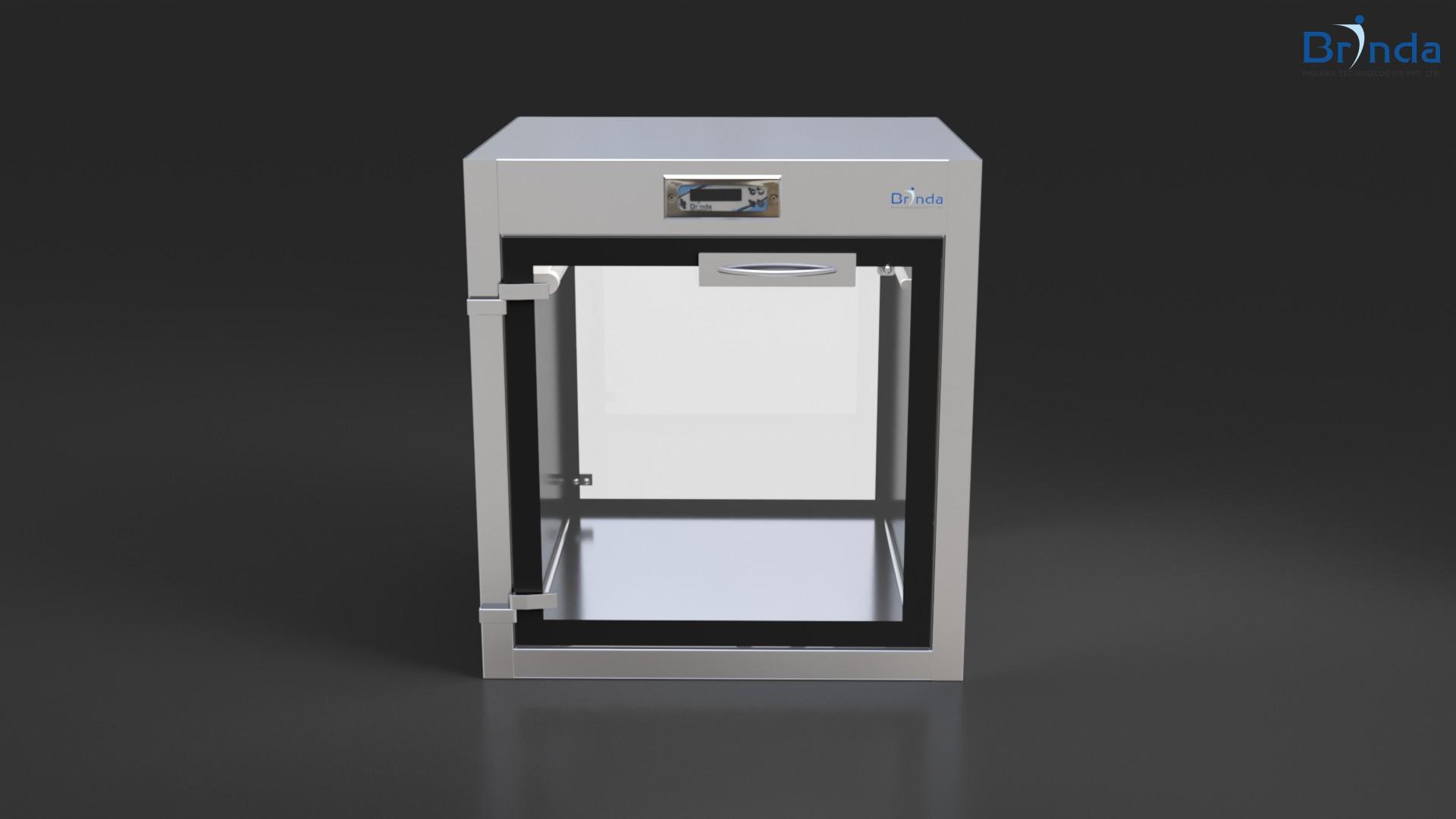

Introducing our Static Pass Box – the ideal solution for controlled access and contamination prevention. Our Static Pass Box offers seamless material transfer while adhering to the highest cleanliness standards. With advanced features and robust construction, it ensures a hygienic environment for critical operations. Equipped with an interlocking mechanism and HEPA filters, our Pass Box prevents cross-contamination and delivers superior air purification. Safety features like door open alarms and a reliable fire suppression system provide added protection. Discover the efficiency and reliability of our customizable Static Pass Box for your specific industry needs.

Brinda Pharma Technologies is a leading manufacturer & exporter of quality clean room air showers for various applications in the following areas:

Our Static Pass Box guarantees a highly secure and controlled environment for transferring materials, mitigating the risk of contamination and maintaining process integrity.

Designed to surpass even the strictest cleanliness standards, our Pass Box creates a sterile and particle-free environment, essential for safeguarding sensitive operations.

Crafted with premium-grade materials, our Static Pass Box exemplifies durability, ensuring reliable performance and longevity despite demanding usage.

Our Pass Box features an innovative interlocking mechanism that permits the opening of only one door at a time, guaranteeing stringent containment and effectively preventing cross-contamination.

Equipped with top-of-the-line HEPA filters, our Pass Box effectively captures and eliminates airborne contaminants, maintaining unparalleled air quality during material transfers.

Seamlessly navigate the Pass Box’s intuitive control panel, facilitating effortless operation, reducing downtime, and optimizing overall efficiency.

Take contamination control to new heights with optional UV lamps, providing an additional layer of powerful disinfection, eradicating harmful microorganisms.

Our Pass Box boasts advanced safety features, including door open alarms that promptly alert users if a door is inadvertently left ajar, ensuring a secure controlled environment. Additionally, a dependable fire suppression system enhances safety measures.

Recognizing the unique requirements across industries, we offer customizable options, tailoring the Static Pass Box to your specific needs and ensuring optimal performance in your environment.

Designed for practicality, our Pass Box’s sleek design and smooth surfaces facilitate easy cleaning and sterilization, reducing maintenance efforts and upholding a hygienic environment.

The working principle of our Static Pass Box revolves around controlled access and contamination prevention. It functions as a secure barrier, allowing material transfer while maintaining a controlled environment. With interlocking doors, HEPA filters, and optional UV disinfection, our Pass Box ensures a clean and safe transfer process. Safety features, such as door open alarms and fire suppression systems, further enhance the controlled environment. Experience reliable material transfer with our Static Pass Box, designed for cleanliness and contamination control.

| Model | Type | Internal Dimension (Working Area) (W X D X H) mm | External Dimensions (W X D X H) mm | Material |

|---|---|---|---|---|

| SPB-WM-450SS | Floor Mounted | 450 X 450 X 450 | 610 X 520 X 660 | S.S. 304 |

| SPB-WM-500SS | 500 X 500 X 500 | 660 X 570 X 710 | S.S. 304 | |

| SPB-WM-600SS | 600 X 600 X 600 | 760 X 670 X 810 | S.S. 304 | |

| SPB-WM-750SS | 750 X 750 X 750 | 910 X 820 X 960 | S.S. 304 | |

| SPB-FM-900SS | 900 X 900 X 900 | 1060 X 970 X 1063 | S.S. 304 | |

| SPB-FM-1000SS | 1000 X 1000 X 1000 | 1160 X 1070 X 1163 | S.S. 304 | |

| SPB-FM-1200SS | 1200 X 1200 X 1200 | 1360 X 1270 X 1363 | S.S. 304 | |

| SPB-FM-1500SS | 1500 X 1500 X 1500 | 1660 X 1570 X 1663 | S.S. 304 |

| Accessory | Description |

|---|---|

| UV Lamp | Effective ultraviolet (UV) lamp for thorough disinfection |

| HEPA Filter | High-efficiency particulate air (HEPA) filter for clean air |

| Interlocking System | Secure interlocking mechanism for controlled access |

| Control Panel | User-friendly control panel for easy operation |

| LED Lighting | Energy-efficient LED lights for enhanced visibility |

| Door Open Alarm | Audible alarm to prevent accidental door left open |

Static pass boxes are commonly used in various industries, including pharmaceuticals, biotechnology, healthcare, electronics manufacturing, research laboratories, and cleanroom environments. They are used to transfer materials, equipment, and samples between controlled areas with different cleanliness levels.

As a leading manufacturer and exporter we provide deliver orders across the world. We also provide products with installation & validation, as well as an annual maintenance contract to ease your operation.

The key benefits of using a static pass box include: Contamination control: It helps maintain the cleanliness and integrity of controlled environments by minimizing the risk of particle and microbial contamination during material transfer. Workflow efficiency: Static pass boxes enable the efficient and organized transfer of materials, reducing the need for personnel movement between cleanrooms or controlled areas. Safety enhancement: By providing a physical barrier, static pass boxes protect operators from potentially hazardous materials, such as chemicals or pathogens, during transfer operations. Regulatory compliance: Static pass boxes are designed to meet strict regulatory requirements and guidelines, ensuring compliance with industry standards for cleanliness and safety.

Static pass boxes are designed with interlocking doors to prevent both doors from being opened simultaneously. This design ensures that only one door is open at a time, minimizing the risk of cross-contamination between the clean and non-clean sides. Materials or objects are placed inside the pass box through one door and then retrieved from the other side, maintaining the integrity of each controlled environment.

Yes, static pass boxes come in various sizes and configurations to accommodate different space requirements and material transfer needs. They can be customized to meet specific industry and application requirements.

Routine maintenance for static pass boxes typically involves regular cleaning and disinfection of the interior and exterior surfaces. It's also important to inspect the interlocking mechanisms, seals, and UV light periodically to ensure they are functioning properly. We provide maintenance guidelines and schedules for static pass box.

Yes, static pass boxes can be retrofitted into existing cleanrooms, provided there is sufficient space and compatibility with the cleanroom's design and airflow system. It is recommended to consult with a professional or the manufacturer to determine the feasibility of installation in a specific cleanroom setup.

When selecting a static pass box, consider factors such as the required cleanliness level, material compatibility, size requirements, any specific features or customization needed, and compliance with industry standards and regulations. Consulting with our sales expert can help you choose the most suitable static pass box for your application in a short time.

Yes, static pass boxes can be integrated into existing cleanroom systems. They can be installed in walls or partitions between clean areas, allowing for efficient material transfer without compromising the cleanroom's integrity.

Safety considerations when using a static pass box include following proper procedures for material transfer, avoiding overloading the box, and ensuring that personnel are trained on its operation. Regular maintenance and inspections should also be carried out to address any potential safety issues.

Subject to stringent regulatory standards, including Good Manufacturing Practices (GMP). A proper SOP for operation, cleaning, and maintenance shall be developed to ensure complete compliance. In most cases, authorities are likely to examine the UV light efficiency, burning hours and how often are you replacing it, and whether there is any system or documented procedure for the same.

Smart Cleanroom Tips to Enhance Lab Safety and Productivity Maintaining a cleanroom environment in pharmaceutical labs is not just about

Reduce Downtime & Improve Efficiency with Our Lab Furniture Systems In the pharmaceutical industry, compliance is non-negotiable. That’s why at

Cleanroom Rules Leave personal items outside the controlled environment If items such as keys, wallets, phones, etc. must be brought into

A clean room is a room where the concentration of particles is minimized. Temperature, humidity and pressure parameters are also

© Copyright Brinda Pharma Technologies 2024. All Rights Reserved

Error: Contact form not found.

Error: Contact form not found.